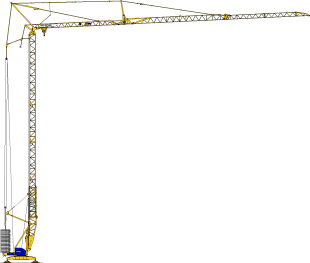

MCR 295 H16

MCR 295 H16 - Smart and compact design specially adapted to High cramped or very obstructed sites. Potain Center of Excellence design maximizes your productivity.

Docmentation

MCR 295 H16

SPECIFICATIONS

Operational compact dimensions

- Optimized counter jib length 8.3 m

- Minimized out of service radius 18 m - 22 m

- 2.9 m to 5 m minimum radius in service

- Optimal packaging for reduced shipping costs

- Minimized component dimensions for easy transportation

- Complete transport in containers 6 HC 40’ only for the entire slewing crane part with 60 m jib

- Simple and safe erection

- Minimized weight of components for simplified assembly

- Simplified mounting of the jib foot with notches on the slewing towerhead

- Easy jib tie bar erection thanks to the standard auxiliary winch

- Rapid pin-connection of the counter-jib High productivity

- Smooth movements due to frequency control Technology

- Powerful hoisting winches (75 hp - 150/180 hp ) make the MCR 295 ideal for jobsites with pre-cast or heavy loads

- Maximum hoisting speeds from 90 m/min up to 245 m/min.

- Large drum capacity for very tall projects

- Optimized speed depending on the load

- Power Control function available on the 150/180 hp winch for reduced electrical demand

- LVF Optima Technology

- Extremely accurate and reactive luffing movements through VVF technology 1 min 40s only to completely raise the jib

- Standard 2/3/4 fall reeving

- Optimized load curves can be achived with unique 3-fall rope reeving

- Vision cab with Dialog VISU indicators user-friendly operating cab with exceptional visibility on jobsite

- RVF Optima+ slewing system

- Slewing speeds up to 0.8 rpm

MANITOWOC GLOBAL SITE

MANITOWOC GLOBAL SITE MCR 295 | pdf | Data Sheet

|3.06 MB

MCR 295 | pdf | Data Sheet

|3.06 MB