Manitowoc Potain offers a range of reliable and efficient top-slewing tower cranes designed to handle the vertical demands of modern construction. These construction cranes, available in topless, hammerhead, and luffing tower crane models, are essential for lifting and manoeuvring heavy materials on large-scale construction sites.

Key Types of Top-Slewing Tower Cranes

Choosing the right crane depends on the specific needs of your project. Below are the main types we offer:

1. Topless Tower Cranes

Topless tower cranes are designed without a tower head, which allows them to work efficiently on sites with multiple cranes or height restrictions. Their compact design minimizes interference, making them ideal for crowded urban environments.

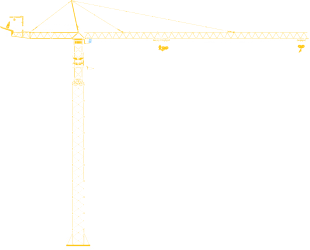

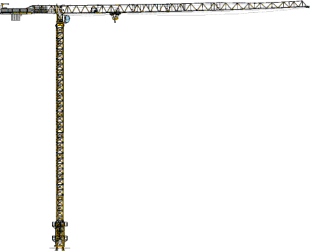

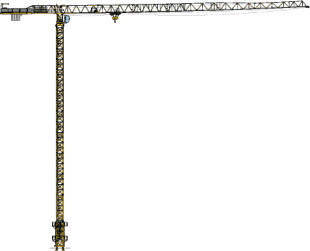

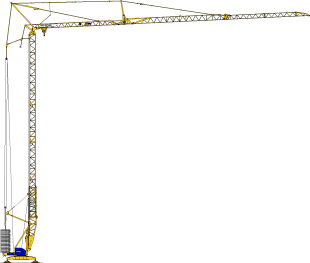

2. Hammerhead Cranes

Hammerhead cranes are a staple in the construction industry. Their horizontal jibs allow for maximum load lifting and accurate placement. Known for their versatility, hammerhead cranes are perfect for general construction projects that require heavy lifting and long working radii.

3. Luffing Tower Cranes

Luffing tower cranes are the go-to choice for projects in confined spaces. Their jib can be raised or lowered to accommodate tight spaces without compromising lifting capacity. Luffers are particularly useful for high-rise building construction, where space is often at a premium.

Efficient Design for Heavy Machinery Tasks

Each building construction crane in our lineup features a robust vertical mast and horizontal jib that work in tandem to ensure exceptional stability and lifting power. The slewing mechanism allows full 360-degree rotation, ensuring materials can be delivered precisely to any location on the construction site.

Anchored for Stability

Manitowoc Potain cranes are engineered to be securely anchored to the ground or attached to building structures, ensuring safe and controlled operations under all conditions. This stability is critical for heavy machinery operations, particularly in the construction of tall buildings and skyscrapers.

Why Choose Manitowoc Potain Top-Slewing Cranes?

- Comprehensive range of topless, hammerhead, and luffing tower cranes

- Reliable performance for heavy lifting tasks

- Precision placement with 360-degree slewing capabilities

- Detailed crane load charts for safe operations

- Industry-leading dealer network and customer support

Get the Right Crane for Your Project

The tower crane price varies depending on model type, size, and capacity. Our team is ready to help you choose the right option for your project’s needs and budget. Whether you require a topless model for urban environments or a luffing tower crane for tight spaces, Manitowoc Potain offers reliable and efficient solutions to elevate your construction projects.

MANITOWOC GLOBAL SITE

MANITOWOC GLOBAL SITE